Chongqing's automotive industry thrives

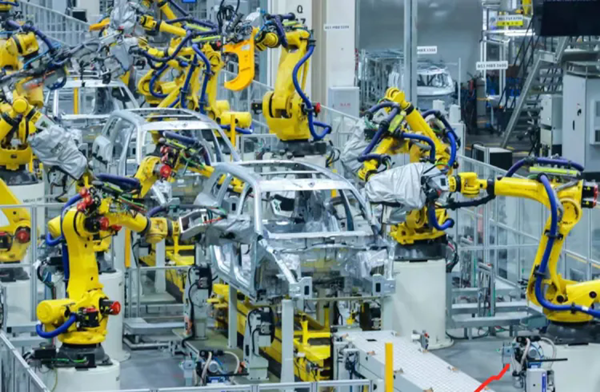

An automotive production line in Liangjiang New Area, Chongqing. [Photo/WeChat account of Liangjiang New Area]

Chongqing's automotive production reached 1.21 million units in the first half of this year, with new energy vehicles accounting for 391,000 units, a year-on-year growth of 150 percent, according to statistics released by the Chongqing Municipal Economic and Information Commission on July 26.

This strong performance is largely attributable to the city's systematic planning and comprehensive advancement, particularly in the smart and connected NEV sector.

Specifically, the city's automotive industry has exhibited clear trends towards high-end, intelligent, connected, clustered, and green development, showing a positive and upward trajectory. The strong breakthrough of the Seres AITO M9 exemplifies Chongqing car manufacturers' efforts to carve out a new competitive edge in the NEV sector.

Chongqing is seizing the opportunity to advance in the smart and connected NEV field, supporting companies like Changan Auto and Seres in accelerating their technological and product layouts. The city continues to launch mid-to-high-end brands such as Deep Blue, Avita, and AITO.

The city is vigorously promoting the enhancement of product development and digital capabilities among vehicle manufacturers like Changan, Seres, and Great Wall, making cars smarter.

Chongqing currently boasts a comprehensive range of NEV technologies, including pure electric, plug-in hybrid, range-extended, hydrogen fuel cell, and battery swapping. Major vehicle products generally achieve L2-level autonomous driving capabilities or higher.

The city has established 340 digital workshops, 50 smart factories, 11 innovation demonstration factories, and 12 pilot applications of 5G+ industrial internet and fully connected 5G factories in the automotive sector.

The Seres Automotive Super Factory in Liangjiang New Area, driven by digitalization and intelligence, has become a global benchmark smart factory, integrating over 3,000 robots for collaborative operations, achieving 100 percent automation in key processes and 24-hour online quality monitoring. Its 10,000-ton integrated die-casting machine ensures manufacturing precision, contributing to industry-leading product quality.

Changan Auto, in collaborating closely with Huawei, China Unicom, and other enterprises, has built a globally leading 5G intelligent factory, widely applying more than 40 advanced technologies, such as 5G, AI, digital twins, photovoltaic power generation, and integrated vehicle software testing. This has resulted in a 20 percent increase in manufacturing efficiency, a 20 percent reduction in costs, and a 19 percent decrease in energy consumption.

Chongqing is planning to build 3,000 smart intersections and 4,000 roadside units, covering 5,000 square kilometers and 5,000 kilometers of roads, respectively. The city aims to create 13 application scenarios for government, enterprise, and individual users in stages, striving to enable smart cars to run on smart roads through a combination of smart vehicles, intelligent roads, and powerful cloud infrastructure.

Chongqing is focused on developing a world-class smart and connected NEV industry cluster led by NEV manufacturers, and the city is implementing a special action plan to enhance the component industrial cluster.

On one hand, the city is intensifying investment attraction efforts, comprehensively reviewing upstream and downstream products and enterprises in the industrial chain based on the needs of vehicle and main chain enterprises, and aiming for vertical integration and horizontal clustering.

In the first half of the year, Chongqing secured 179 automotive industry projects with a contract value of 130 billion yuan ($17.93 billion).

At the same time, the city is vigorously promoting the transformation and upgrading of traditional component enterprises and the cultivation of innovative enterprises. In the first half of the year, 51 traditional component enterprises completed transformation and upgrading, and 32 newly introduced enterprises started production, entering the city's smart and connected NEV industrial chain.

The city saw the emergence of three potential unicorn enterprises in the automotive component field and over 20 gazelle enterprises.

Chongqing's smart and connected NEV components currently cover three major systems, 12 major assemblies, and 56 parts, achieving comprehensive coverage and clustered development. The component technology levels of companies such as Fudi Power Battery, Qingshan Electric Drive, Longrun Electric Steering, Bosch Hydrogen Power, and Beidou Intelligent Cockpit are the most advanced in China.

Chongqing is also speeding up the promotion and application of NEVs, advancing the development of a green and low-carbon transportation system. The city is fully advancing pilot work on the comprehensive electrification of public domain vehicles, accelerating the electrification process in public sectors such as government, taxis, and urban buses in 10 key districts and counties.

In the first half of this year, Chongqing promoted 100,500 NEVs, a year-on-year increase of 40.56 percent, bringing the total number of promoted NEVs to 535,000. To support infrastructure construction, the city built 58,100 new charging piles, a year-on-year increase of 42.69 percent, bringing the total number of charging piles to 268,000.

As of the end of June, 167 supercharging stations had been built, with 313 under construction; 363 supercharging piles had been built, with 396 under construction.