Chongqing software startup firm competes with Simens

Updated:2022-12-07

english.liangjiang.gov.cn

"Our industrial software platforms, the Blossim manufacturing execution (MES) system, and Internet of Things (IoT) system can compete with international giants like Siemens," said Lu Yi, general manager of Chongqing Blossim Technology Co.

The company, a startup consisting of only 30 people, is developing industrial software in Southwest China's Chongqing municipality.

An engineer at Blossim Technology provides after-sales service at Guangxi Yuchai Machinery Group Co. on November 10, 2022 [Photo provided to english.liangjiang.gov.cn]

Accuracy of process implementation reaches 95%

Blossim was founded in 2009, providing digital factory solutions for manufacturing enterprises in areas such as mechanical manufacturing, electronic information, auto parts, and rail transit. It has since grown into a national high-tech enterprise.

Despite only having 30 employees, it competes with international giants such as Siemens. Its clients include leading enterprises such as CRRC Corporation Limited, Chongqing Chuanyi Automation Co, and China Aerospace Science and Technology Corporation.

China is home to many different types of manufacturing and has encountered a variety of complex digital manufacturing problems. In such an environment, Blossim Technology has prospered.

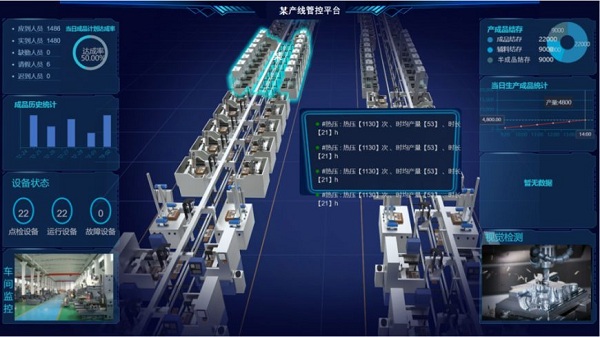

By integrating industrial automation and production management information systems, Blossim's MES and IoT systems interconnect production management and equipment operation and integrate with factory-level manufacturing operation management (MOM), ERP, PDM, and visual AI systems to improve production efficiency.

The accuracy of process implementation is 95 percent, the transparency of production progress is 100 percent, and the accuracy of tooling inventory is 99.5 percent.

Production control platform built by Blossim Technology. [Photo provided to english.liangjiang.gov.cn]

Chongqing's software industry to join nation's upper echelon

Lu Yi, the founder of Blossim, is a veteran of factory informatization. Many years ago, Lu realized that the manufacturing industry was trending toward data management, meaning industrial software has great potential.

In 2009, famous enterprises such as Honeywell, Chongqing Microsoft Technology Center, and Kingdee set up operations in Chong's Liangjiang New Area. Lu saw strong prospects for software and information industry agglomeration and decided to establish Blossim in the area as well.

Lu's decision paid off. Hundreds of office buildings now fill Liangjiang New Area, which is home to more than 5,000 software and information technology enterprises. The area also formed an ecosystem of industrial design, manufacturing, control safety, and detection.

From January to September this year, Chongqing's software and information service industry saw revenue of 201.1 billion yuan ($28.2 billion), up 12.6 percent year-on-year. More than 1,800 new companies joined the city's software and information service track, bringing in over 30,000 employees, including 2,600 top talents.

More and more industrial players are entering Chongqing's software market. Lu sees intensifying competition and new opportunities brought about by industrial agglomeration.

Indeed, when it comes to boosting agglomeration, Chongqing is quite ambitious. This July, the government released a plan for the software and information service industry.

It proposes that by 2025, Chongqing add tens of thousands of software enterprises and 200,000 employees in the sector. Software revenue should increase to 100 billion yuan, driving the city's software business output to 500 billion yuan by the end of 2025. Chongqing's software industry is expected to join the nation's upper echelon.

Hundreds of office buildings are located in the Liangjiang New Area. [Photo/Chen Wensen]

Video

John Edwards, the UK trade commissioner for China, praised Chongqing over its rise as a burgeoning center in intelligent manufacturing.